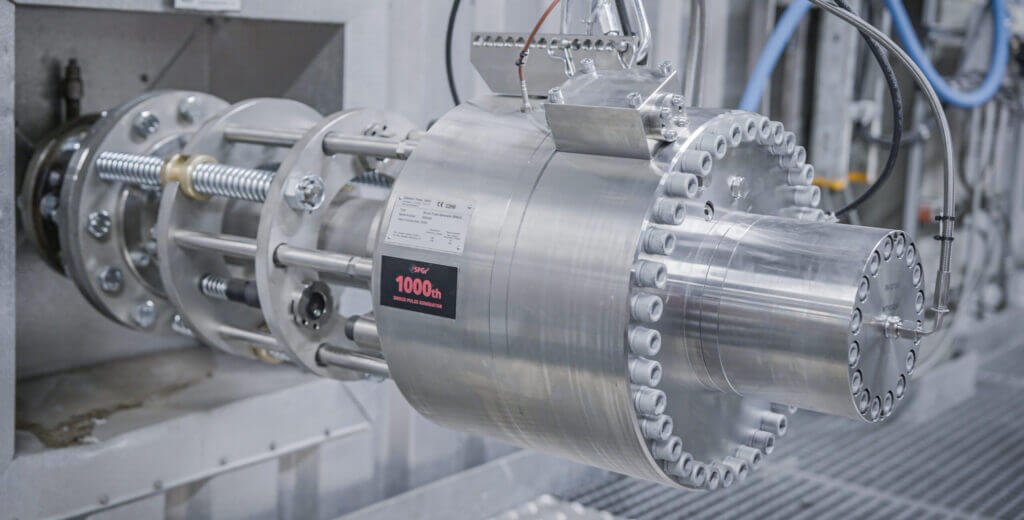

The Swiss-based Explosion Power company, which we represent, manufactures a high-tech Shock Pulse Generator (SpGr) that enables the online cleaning of ash formed inside boilers in coal, biomass, and waste-fired boilers.

Thanks to the proven cleaning technology and the system that operates automatically every hour, the ash accumulated on the pipes such as membrane walls, superheaters, and economizers inside solid fuel boilers is continuously cleaned, enabling the boiler to operate at high efficiency and performance.

This system, currently used as the most effective boiler cleaning method in the world, is operating in over 1,000 units worldwide.

Cleaning Method

With our proven online cleaning technology, deposits on heat exchanger surfaces such as membrane walls and pipe bundles in large boiler plants can be successfully prevented.

Sediment can be significantly reduced in refurbishment projects. This innovative Shock Pulse Technology enables you to achieve longer operating times, higher boiler availability, and reduced maintenance and operating costs!

Over 1,000 Shock Pulse Generators (SPG) are permanently cleaning critical boiler areas in process plants, as well as multiple fuels such as municipal solid waste, industrial waste, and coal.

Waste, industrial, coal-fired power plants, and process facilities are permanently clean!

Standardized Shock Impact Robust and durable generators Innovative technology

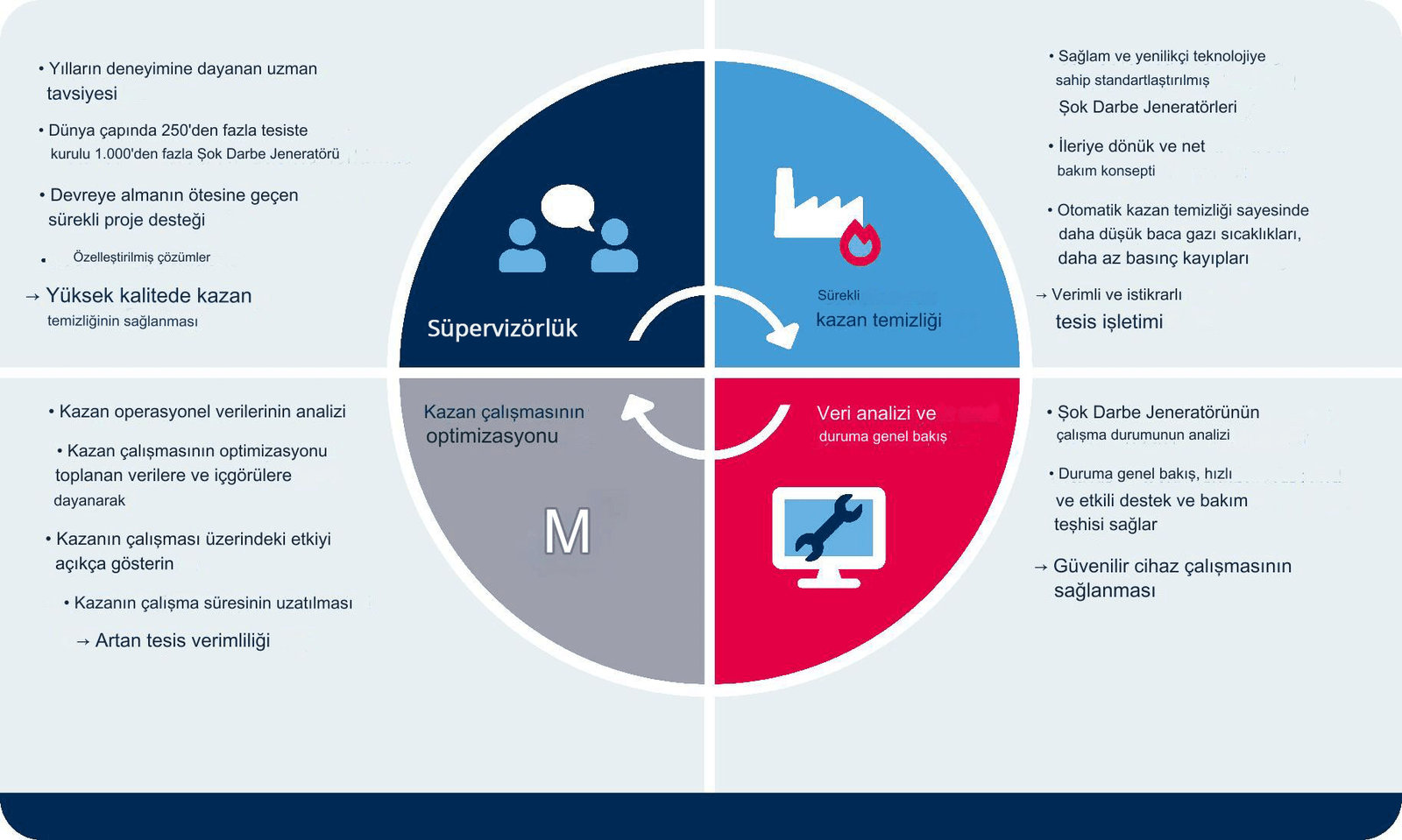

Expert advice based on years of experience

experience

Customized solutions for automatic boiler cleaning

Efficient and stable facility operation

Ensuring high quality in boiler cleaning

Analysis of boiler operating data Optimization of data analysis

Overview of the situation: fast and effective support and maintenance

Provide reliable equipment

Extension of the boiler operating time

Increased plant productivity